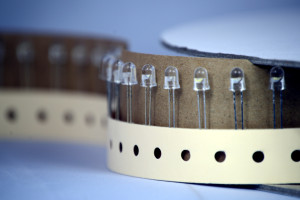

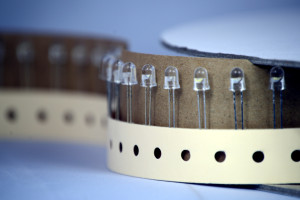

We also offer Radial-tape and reel services. We have the ability and equipment to tape a vast range of leads spacing for all your components We feature high speed automated machines that are able to produce LARGE production quantities; there is never a delay in your parts.

Capabilities

- Lead Spacing.100,.138,.150,.200, .250,.300.,350 and .400

- Lead Straightening

- Lead Stripping

- Lead Trimming

- Ammo Packing

- TO-92 Transistor Lead Forming and taping.

Lead Forming

- Mid America has extensive tooling for a vast array of forming need

- Mid America is a true expert at converting through-hole devices to SMD.

- A tremendous variety of through-hole forming options are available At Mid America.

- We have machines and tooling from virtually all of the leading manufacturers in this category.

Our final inspection

Every part inspected as part of our three stage inspection process to ensure product quality in exceeding EIA Standards. All components are taped to the EIA Standard RS-468-B unless otherwise specified.

Delivery

Normal turn around time is 3 working days. When needed, we will provide same day service without any additional charge.

What is Radial Taping?

Radial taping refers to a method of wrapping a material, such as a cable or wire, with a tape that is wound spirally around the material in a radial direction. The tape used in radial taping is typically made of a flexible material, such as polyester, that can conform to the shape of the material being wrapped.

How is Radial Taping used?

Radial taping is commonly used in the manufacturing of electrical cables and wires, where it is used to provide mechanical protection, insulation, and other properties. For example, radial taping can help prevent damage to the cable from abrasion, puncture, or other mechanical stresses. It can also help to improve the electrical properties of the cable, such as its capacitance or resistance.

How is Radial Taping done?

The radial taping process can be performed manually or using automated machinery. In manual radial taping, the tape is wrapped around the cable by hand, with the tape held at a specific angle to ensure a consistent wrapping pattern. In automated radial taping, the tape is fed into a machine that applies the tape in a controlled and consistent manner.

Overall

Radial taping is an important process in the manufacturing of electrical cables and wires, and it is used to provide a range of mechanical and electrical properties that are essential for their performance in various applications.

Call Mid America at 1-888-629-6646 or fill out the form below to place an order or for more information.